Our History

1945

Lt. Gayle V. Morrison returns home from a tour of duty in the South Pacific as a decorated B-24 bomber pilot. Gayle and Meredith “Mitzi” Winship finally carry out long made plans to be married. After the reception and much-needed honeymoon, the newlyweds head towards their future in the lumber industry. Yuba City Planing Mill and Lumber Company is founded.

1948

Together with his partners, Henry Buford Williams and Carl A. Williams, Gayle Morrison carries out plans for building our namesake, Sunset Moulding Company. Despite starting with only a single moulder and less than a dozen men, their reputation of producing top-shelf mouldings spread nationwide.

1960’s

Until this point Sunset Moulding was strictly a producer of lineal mouldings, but by 1960, the increasing demand for long-length products led the company to start producing finger-jointed mouldings. In order to stay at the forefront of innovation, Sunset ordered its first finger joint machine from Germany. As demand for this product grew, Sunset became the largest privately-owned, single-site moulding mill in the country.

1970’s

Gayle and Mitzi Morrison become sole owners of Sunset Moulding Company by buying out their former partners. Sunset enjoys substantial growth throughout the decade. The company employs over 300 people, expands to multiple locations, and is continuing to grow despite the ongoing energy crisis.

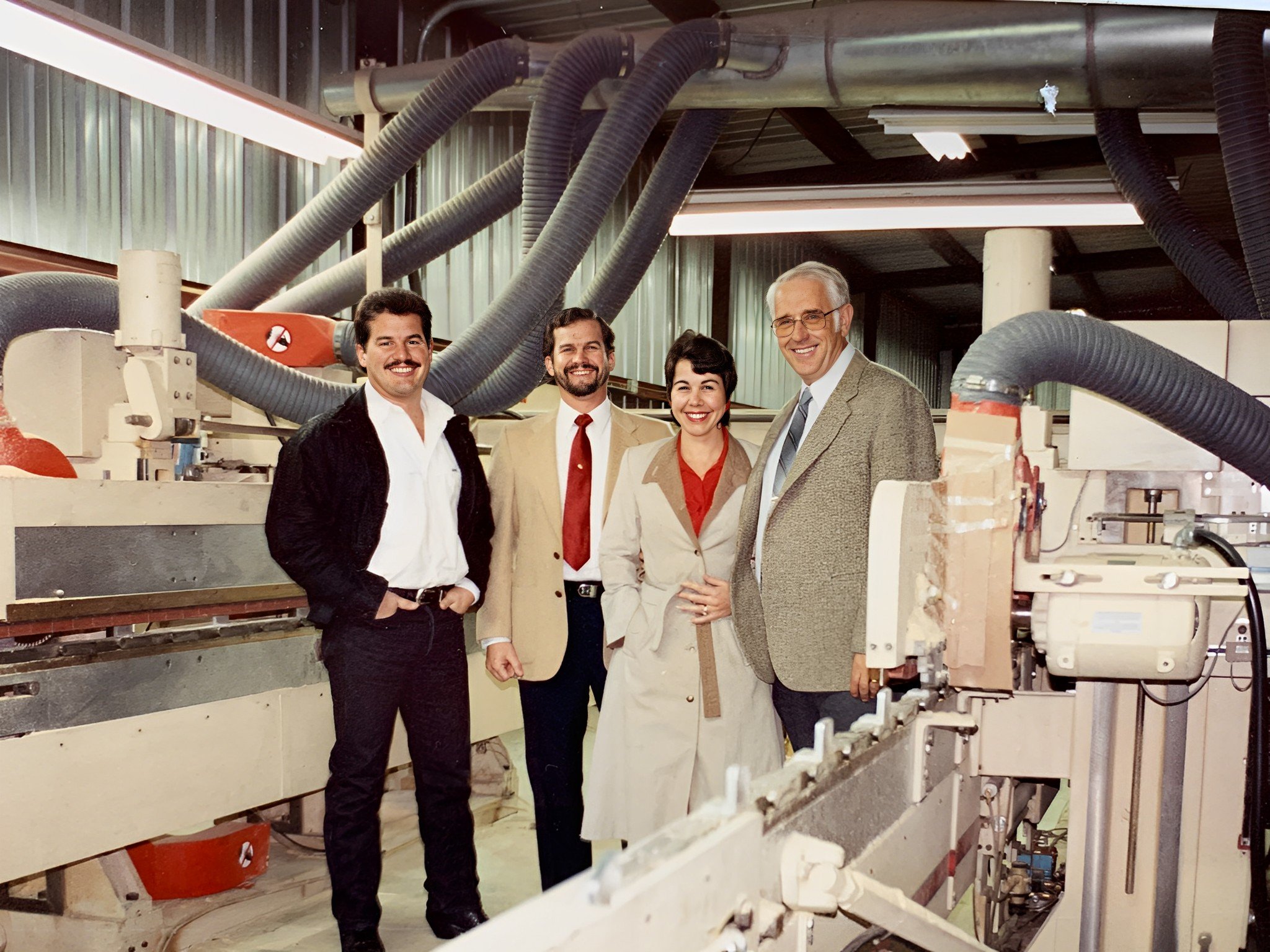

1980’s

In the 1980s, the domestic lumber supply in the United States shrank dramatically due to the protection of the Spotted Owl, which forced Sunset Moulding to change direction and find new sources of supply. John Morrison was tasked with finding this new source and eventually discovered radiata pine in New Zealand. This was the first time that this type of wood had been used in the mass production of mouldings. The partnerships formed with New Zealand allowed Sunset Moulding to meet the growing demand for primed mouldings at the retail level, leading to a period of dramatic growth for the company.

1990’s

The changing of the guard. After a long and auspicious career, our founder Gayle Morrison steps down and names his trusted friend and longtime employee Ken Olson as acting president. Ken Olson would eventually retire in 1997 and pass the presidency on to Gayle’s son John Morrison, who still leads us to this day. His first order of business – launching Suntrim™, our brand of MDF mouldings.

2000’s & beyond:

The launch of Suntrim™ was a huge success and led to MDF mouldings becoming Sunset Moulding's largest product line. The increased demand for these products resulted in the reconfiguration of the company's Live Oak, California facility into a dedicated MDF manufacturing plant and the purchase of their first out-of-state facility in Idabel, Oklahoma. In addition, the third generation of the Morrison family joined the company, with Mike Morrison being promoted to Vice President of Production and Chase Morrison tasked with finding and developing new product lines. Together, they developed a redwood finger-joint program and installed a thermal modification kiln.

Sunset Moulding is now celebrating over 75 years of making quality mouldings as a family-owned and operated business.